Foam FAQs

Common (and not so common) Questions & Answers

Frequently Asked Questions about Foam

Which Types of Foam can I Cut?

EPS Foam

Expanded Polystyrene is the most common foam for hot wiring as it is strong, lightweight, inexpensive and cuts very easily with a hot wire or hot knife. It is usually white and is made of tiny foam bubbles. You can find 2″ x 4′ x 8′ sheets in home supply insulation areas. They sometime have a thin sheet of silver Mylar covering them, which should be peeled off. EPS is often used for packaging appliances. EPS is typically manufactured as large 4′ x 3′ x 8′ blocks. If you have a need for large foam blocks or large quantities of foam we’ll help you find the nearest supplier.

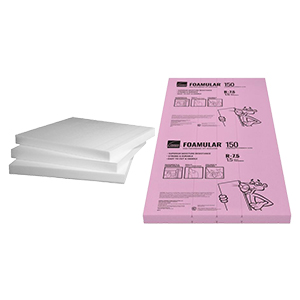

XPS Foam

Extruded Polystyrene is usually a denser foam that is very smooth. Although the cuts are slower than EPS, they are very clean and smooth. It is often used for projects that have intricate detail. This includes DOW Styrofoam, Owens Corning Pinkboard (Foamular), and DOW Blueboard. These foams are commonly found in home supply insulation departments. We have a white XPS that is even smoother than the insulation foams that we sell as Art & Sign Foam.

Polyethylene Foam

PE foam, like Polystyrene, can be found in expanded or extruded forms. Cuts much slower than Polystyrene. PE foam is usually a dark gray and has a rough texture. PE is commonly used for instrument cases. It does not off-gas like polyurethane, so it will not damage expensive instruments that are stored for long periods of time. This is a closed cell foam, meaning it does not absorb water.

EVA Foam

Ethylene-Vinyl Acetate is a flexible foam used in things like exercise mats and crafting supplies. Very popular with Cosplay artists. Many EVA foams can be cut and embellished with our tools. We suggest getting a kit with a variable power supply because some require higher heat while most require lower heat. Don’t confuse this with foam rubber, which cannot be cut with a hot wire.

Expanded Polypropylene

EPP is often used for RC airplanes and packaging sensitive instruments because it is semi-rigid but flexible enough to survive crash landings. Cuts similarly, but is more rigid and slightly smoother than Polyethylene foam. This is a closed cell foam.

Other

Two Part Polyurethane

Builders using two part expanding polyurethane foam, like Great Stuff, often use a hot wire to clean up the edges, but not all of these can be cut with heat and ALL of them give off toxic fumes when cut with heat. Use respirators and cut in well ventilated areas.

Plastics

Although some plastics can be cut with a hot wire or hot knife, the cutting will be very slow and the fumes will likely be toxic. Coroplast can be cut, though slowly, with a hot wire or hot knife.

Some people like to use hot wire tools to cut nylon and polyethylene rope because it singes and seals the ends.

If you are unsure whether or not this tool will cut the foam you intend to cut, please check with us and the manufacturer of the foam before buying.

Q: Are the fumes that are given off when cutting polystyrene foams (EPS or XPS foams) with hot wire tools dangerous?

A: Ventilation is always strongly suggested, but the smoke that you may encounter while cutting EPS foam is primarily CO2 and water vapor, which are far less harmful than other common art products like aerosols and paint thinners. The toxic values are far less than wood-smoke, which contains tars, resins, creosote, and acetic acid. The dust from cutting with saws and sanding EPS foam is more harmful than the fumes encountered while cutting foam with a hot wire tool. Always wear a good quality dust mask when saw cutting or sanding polystyrene foams.

Hot-Wire Foam Cutting Exposure Assessment During Theatrical Staging

In 2017 the International Alliance of Theatrical Stage Employees did an extremely thorough study using workers who spent anywhere from 1 hour to 8 hours a day cutting foam. Here is their conclusion:

“The results suggest that the hot-wire foam cutting workers and nearby bystanders are not at a risk of over exposure to fume generated by this task under conditions similar to those present during this assessment.”

The tests were performed in warehouses, one with a fan blowing and the other with the bay door open. They also had sensors placed on special masks that the subjects wore while cutting.

Here’s a link to the article:

https://www.iatse.com/_content/documents/public/IA170101%20Hot-Wire%20Foam%20Cutting%20Exposure%20Assessment%20Oct%204%202017%20FINAL.pdf

We did a search and found that the composition of the fumes from burning firewood and even a scented candle are worse than the fumes from cutting EPS foam with a hot wire. Even with this in mind I always try to cut in well ventilated areas and use a fan when I’m not.

On the other hand, EPS dust particles are dangerous carcinogens. A dust mask is an absolute necessity when dust particles are present. Always check with the manufacturer of the foam you are using to make sure that there are no health or safety hazards when cutting their foam with hot wire tools. Keep in mind when you read the Material Safety Data Sheets (MSDS) for the foam you look up that they often are referring to possible safety hazards when manufacturing foam, not cutting it.

You can call our toll free number at  1-866-735-9255 and we can give you the tech-support number for DOW which manufactures Styrofoam. They told us that the fumes from cutting their foam with a hot wire are not toxic, but cutting should still be done in a well-ventilated area. (On the other hand we have had many personal testimonials claiming that they have become addicted to foam cutting. Could it be the fumes or is foam sculpting is way too much fun?)

1-866-735-9255 and we can give you the tech-support number for DOW which manufactures Styrofoam. They told us that the fumes from cutting their foam with a hot wire are not toxic, but cutting should still be done in a well-ventilated area. (On the other hand we have had many personal testimonials claiming that they have become addicted to foam cutting. Could it be the fumes or is foam sculpting is way too much fun?)

Q: I was told foam might present a fire hazard, is this true?

A: For those using foam for stage props and backdrops instead of plywood, fire marshalls may ask questions about the fire safety of foam. EPS foam is now commonly used all over the world in huge theaters and auditoriums with thousands of people. Once the fire department looks at the fire spread and toxicity of foam compared to wood and cloth, they are ecstatic. You can hold a torch to EPS foam and it will stop melting/burning the second the flame is gone. The ‘smoke’ is mostly hydrocarbons and water vapor. To get the polystyrene foams to actually combust and burn you have to have an extremely hot fire, much hotter than our tools get, burning directly on the foam to begin with.

You can also call or look on the DOW Chemical site, as they hold the patent on its manufacturing process. They have all the Material Safety Data Sheets (MSDS).

For architectural or large projects where fire could be a potential danger, we recommend all foam is coated to prevent spread of fire. Below is the section from the Foam Coat MSDS showing the fire data:

SECTION IV

FIRE AND EXPLOSION HAZARD DATA

Flash Point (Method Used): Non-combustible.

Extinguishing Media: Use extinguishing media appropriate for surrounding fire.

Special Fire Fighting Procedures: None

Unusual Fire and Explosion Hazards: None

Special Fire Fighting Protective Equipment: None

Q: Is using foam “Earth Friendly”?

A: Expanded polystyrene (EPS) foam is recyclable and is a pre-existing waste byproduct of petroleum refinement. It takes less energy to make than paper and causes less pollution in the process. A great way to acquire foam and be “green” in the process is to check with local appliance and computer stores, which may normally throw away the EPS foam they accumulate from packaging.

Q: What kind of foam would you recommend for building layouts with Dept 56 buildings or for trains? Do the pink and blue foams cut as well as the white? Which is better for making a rigid structure?

A: Most people use the white beaded foam (called EPS for expanded polystyrene) as it is the least expensive and easiest to find and cut. It is great for making terrain like hills and mountains. If you need it to be tougher, or want to hide the little beads, you can coat it with our Foam Coat.

The pink or blue foams (sometimes called XPS for extruded polystyrene) are usually used for making detailed structures like walls and buildings. Although they do not cut as fast as the less-dense EPS foam, they cut very well with our hot wire tools. If you want to make a diorama that is very light for storage or portability you can use 2″ or thicker Blue or Pink foam for the structural base of the diorama rather than wood or a table. One of the other advantages of using foam as a base is that you can use the hot wire tools to make holes to bring all of your unsightly wiring straight down all the way to where your electrical hookups are, just like underground utilities.

Q: Can your tools be used to cut polyurethane foam? (sold as camera and gun case foam)

A: We have been getting a ton of requests for a ‘museum quality’ foam for camera cases and gun cases that can be cut with hot wire tools, so we now have a solution. Not only is polyurethane foam difficult to work with as it cannot be easily cut with hot wire tools, but it also off-gasses and degrades and damages the instruments it is supposed to protect. We recommend that the polyurethane foams only be cut with a blade or saw.

Q: Can your tools be used to cut polyethylene foam? (sold as camera and gun case foam, “Plastazote” or “Ethafoam”)

A: Hot wire tools will cut polyethylene foam, but will give a slower cut as they are generally more dense than EPS foam. As these foams are denser, make sure that you don’t put too much pressure on the blade or wire of your tool, as this could cause it to bend and eventually break. The manufacturer of Zotefoams USA told us that their foams are safe when cut with a hot wire. Many of our customers use hot wire tools to cut Ethafoam and other polyethylene foams, but I always suggest that they check with the manufacturer of the foam to make sure it is safe to cut it with hot wire tools.

Q: Can your tools be used to cut polyurethane foam? (sold as upholstery foam and “poly foam”)

A: Polyurethane foam should not be cut with hot wire tools. It needs a ton of heat, gives off toxic fumes, and leaves a lot of melted plastic wherever it is cut. We recommend that the polyurethane foams only be cut with a blade or saw.

Q: Can your tools can be used with PVC-based corrugated sheet like Coroplast?

A: We have done some cutting of Coroplast with our Hot Wire tools and it cuts a bit slow and leaves a ridge that can be broken off. A razor blade is faster for straight cuts, but the hot wire tools come in handy for curves. The Sculpting Tool with the wire just past 5″ long cuts the best. As always, you will need to check with the manufacturer to see if there are any health or safety hazards when cutting their material with hot wire tools.

Q: Will your 4″ hot knife cut 3mm thick craft foam? The brand I buy is Darice Foamies, and I use it to create my own stamps for mixed media art work by gluing pieces to acrylic squares and then inking the foam. Scissors and Exacto knives cannot really create clean cuts. If the 4″ knife won’t work (maybe it’s too long), what would you suggest?

A: I don’t think that this type of foam can be cut with hot wire tools. I looked it up online and although they don’t say what it is made from, I think it is a polyurethane foam which does not cut well with heat, and gives off toxic fumes when cut with a hot wire. If you can find a way to contact the manufacturer maybe they can tell you for sure. We have made some pretty cool stamps out of the DOW Blueboard and Owens-Corning Pinkboard foams. They seem to ink up well without dripping. The 4″ Hot Knife cuts this foam well, but I usually use the Original Scroll Table for better control. With the Scroll Table you can cut a thick piece of foam into your stamp shape, and then slice it up to make extra stamps.

Q: Will your hot wire tools work on Michaels artificial foam pumpkins, or Funkins artificial pumpkins?

A: Those foam pumpkins are typically made out of polyurethane foam, which should not be cut with hot wire tools. Polyurethane needs a ton of heat, gives off toxic fumes, and leaves a lot of melted plastic wherever it is cut.

Q: I want to make a large sculpture of an animal, but can’t find a big enough block of foam. Can you help?

A: If you need help sourcing foam in your area, or if you’d like help connecting with an artist to create a custom foam prop for you, please feel free to give us a call at 866.735.9255 or contact us here.

You can build your own block of foam with sheets of EPS or XPS typically found in 2-4-inch thicknesses as 4-foot x 8-foot sheets and stack them, holding them together with skewers while cutting, and then gluing the pieces together after they are sculpted – we recommend using our Foam Fusion glue. If there is a silver Mylar coating it will have to be removed before gluing. The seams are easily hidden with a little Foam Coat. Check out this dog sculpture in our gallery, where you will see how Colleen glued pieces of pink insulation foam together.

We also sell 12-inch x 14-inch x 22-inch EPS foam blocks on our website.

Q: I am having trouble finding the pink or blue foam in my area. Maybe it’s not cold enough? I did find polyurethane foam sheets with a thin layer of foil on both sides. If I peel off the foil, will the hot tools work on that type of foam or do I need to look harder for the EPS?

A: The polyurethane foam is very toxic and won’t cut well with heat. You should be able to find the white beaded EPS insulation foam though. It often has a thin, clear plastic moisture barrier that peels right off. This is much easier to cut than blueboard and pinkboard. It has a memory, so if it gets squished a little it regains its shape. It is lighter and much less expensive. Usually people who are doing fine scale modeling use the extruded blueboard and pinkboard because it doesn’t have the bubbles. You can put a thin layer of Foam Coat on to cover up the bubble texture if that is an issue. You will find that the white beaded EPS foam when coated with Foam Coat is more economical, nicer looking, lighter, and easier to work with.

Q: What is “open cell foam”?

A: Open cell structured foams contain pores that are connected to each other and form an interconnected network which is relatively soft. The “crunchy” foam found in floral craft projects is an example of open cell foam.

Q: What is “closed cell foam”?

A: Closed cell foams do not have interconnected pores. Normally the closed cell foams have higher compressive strength due to their structures. The closed cell structure foams have higher dimensional stability, low moisture absorption coefficients and higher strength compared to open cell structured foams.

Examples of closed cell foams include expanded polystyrene (EPS), which is made of pre-expanded polystyrene beads, which is why it is sometimes known as bead-board foam. It is generally seen as blue, pink, yellow and green insulation sheets. Extruded polystyrene foam (XPS) is also a closed cell foam, and trade names for XPS foam include “INSUboard,” “Styrofoam,” “Foamular,” “Greenguard” and “Foamcore.”

Q: We need to protect hand gauges while in storage. We will be placing polyethylene foam in Lista cabinet drawers and be cutting out “beds” for various measuring instruments such as: OD micrometers, thread gauges and other various pieces of equipment. We will not be cutting through the foam but be cutting shapes into the foam for the gauges to lay. What tools do you suggest we use?

A: Our tools will cut through polyethylene foam, but not nearly as fast as the white beaded EPS foam. The finer the blade, the faster and nicer the cut. It takes about three seconds to cut one inch and there is a buildup of melted foam that has to be wiped off of the 4″ Hot Knife and Freehand Router in between cuts. I am not sure what your cutting needs are, but rather than buy the K47 Kit, I suggest buying the K44P6 Kit, plus buy the Sculpting Tool separately. The Pro 6″ Knife cuts the foam much quicker than the 4″. I am also concerned that you might break the blade on the 4″ cutting through this tougher foam. Here is a link showing our tools being used to cut some polyethylene foam. We have tried cutting polyethylene foam with more heat, but the residue carbonizes onto the blade to the point where it stops cutting and is very difficult to clean off. You should check with the manufacturer for the Material Safety Data Sheets (MSDS) for their foam when cutting it with heat.

Q: What kind of foam are pool noodles made out of? Can I cut them with your tools?

A: Foam pool noodles are usually made from polyethylene foam, which can be cut with hot wire tools.