Cast Iron Shell Sculpture

Jesse Duke

My name is Jesse Duke, a senior sculpture major at the University of West Georgia. I have recently found hot wire tools and foam to be a great asset in sculpture fabrication. The speed in which a piece can be worked out has been helpful in my work making for quick masters for metal and other casting.

Thus far I have used Styoplast exclusively for coating my pieces but I look forward to trying out the other products Hot Wire Foam Factory offers!

Below is the step by step process (mostly) showing what it takes to make foam turn into metal.

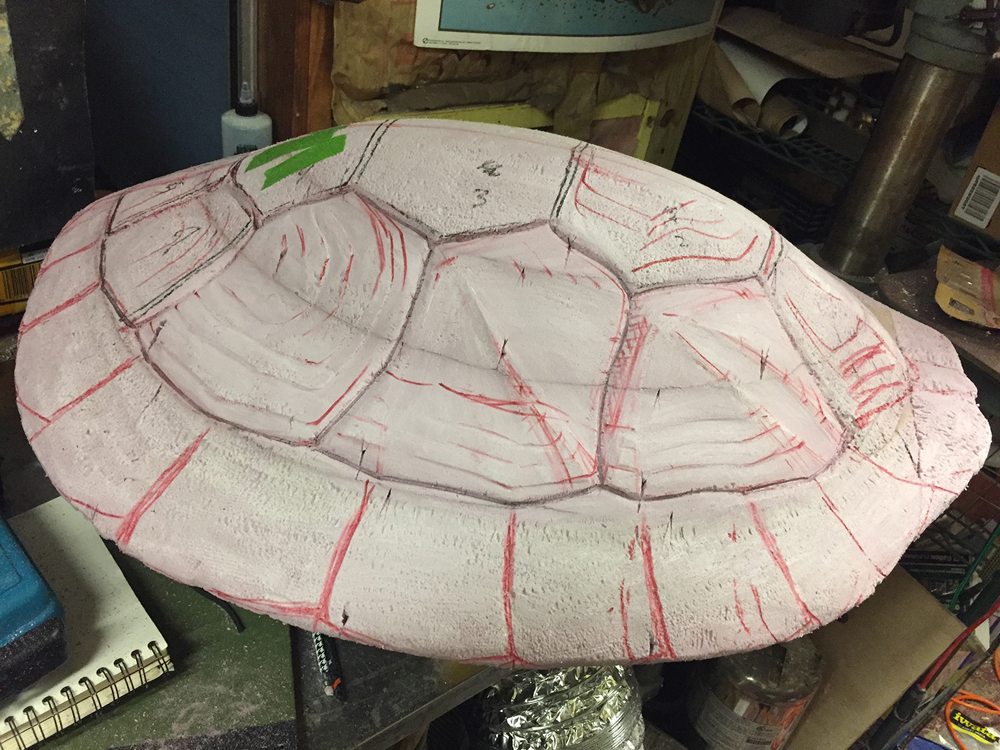

Step 1: After gluing a block of pink XPS foam together, I begin to take material away using the Sculpting Tool, Hot Knife, and Engraver. I also start sanding the contours.

Step 2: Continuing the contouring

Step 3: Using the Engraver to work detail lines into the “scutes.”

Step 4: Styroplast! This stage is the most exciting because I can finally breathe easy, knowing things will be safe and sealed up.

Step 5: Next is the iron casting process. First I made an armature over my foam piece.

Step 6: Sand mold progress. Building a box, filling with chemically bonded sand.

Step 7: Sand mold cured.

Step 8: Two halves of the mold coated in graphite mixture.

Step 9: Pour iron! Get heavy cast! (Sorry I don’t have any photos of this intense stage of the project)

Step 10: Foam shell alongside rusted/painted iron shell. The finished iron shell is approximately 3’x4’, and weighs around 120lbs.