Ultima Weapon Walkthrough

A Step-by-Step Look at Building a Foam Cosplay Prop

Chris Clarke

www.facebook.com/clarkecosplay

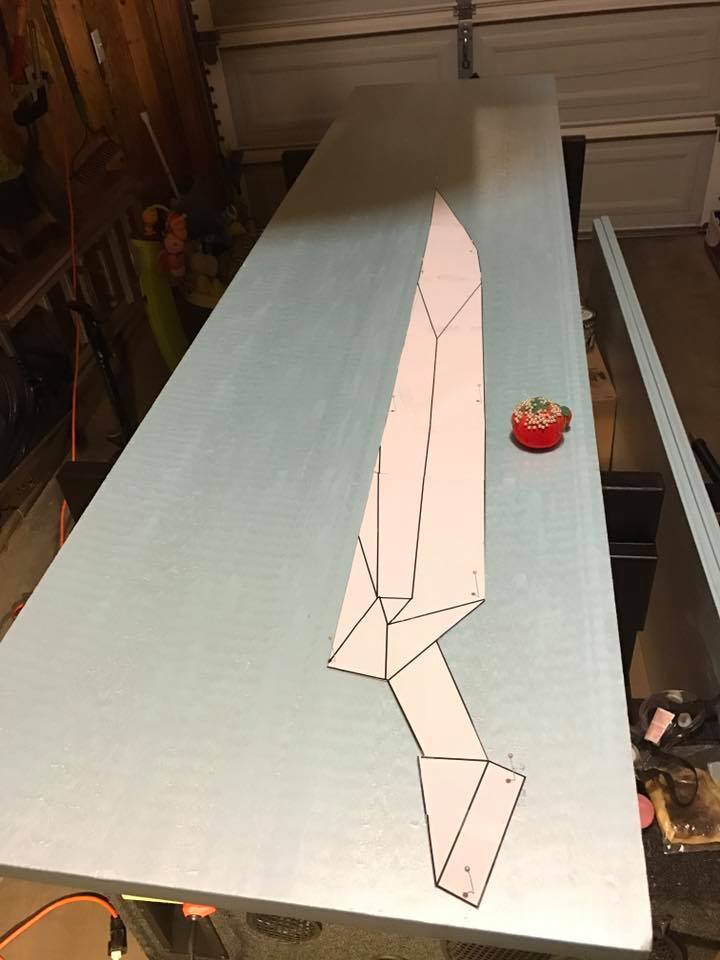

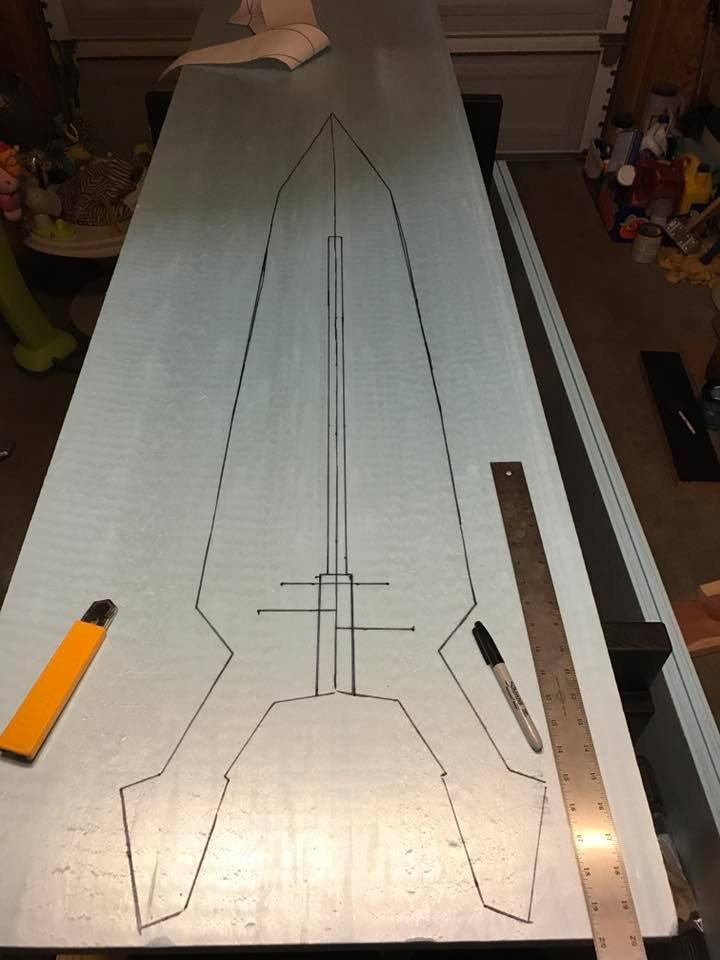

I started this project with a reference picture, which I made a to-scale pattern from using Photoshop. The finished sword is about 5.5 feet long. I chose 5.5 feet by using the game, as according to Cloud’s official game profile, he is 5′ 7″ tall and the sword is almost as tall as him. Initially, I was going to use EVA foam for this but I decided I would use XPS foam. The Hot Wire Foam Factory Sculpting Tool and Wire Tensioner were essentials tools in making this prop!

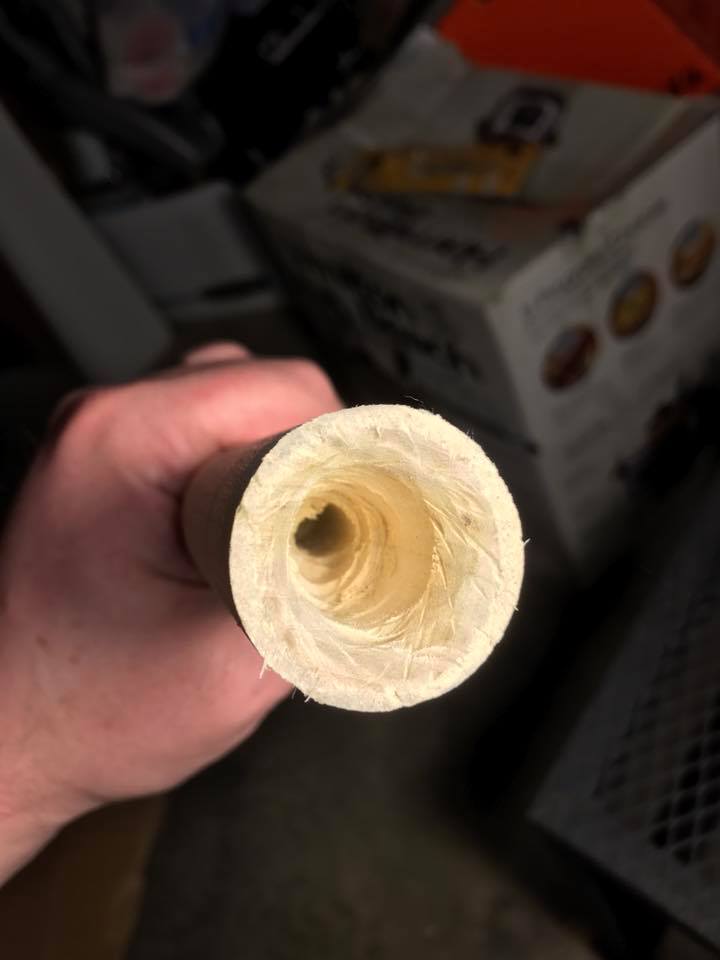

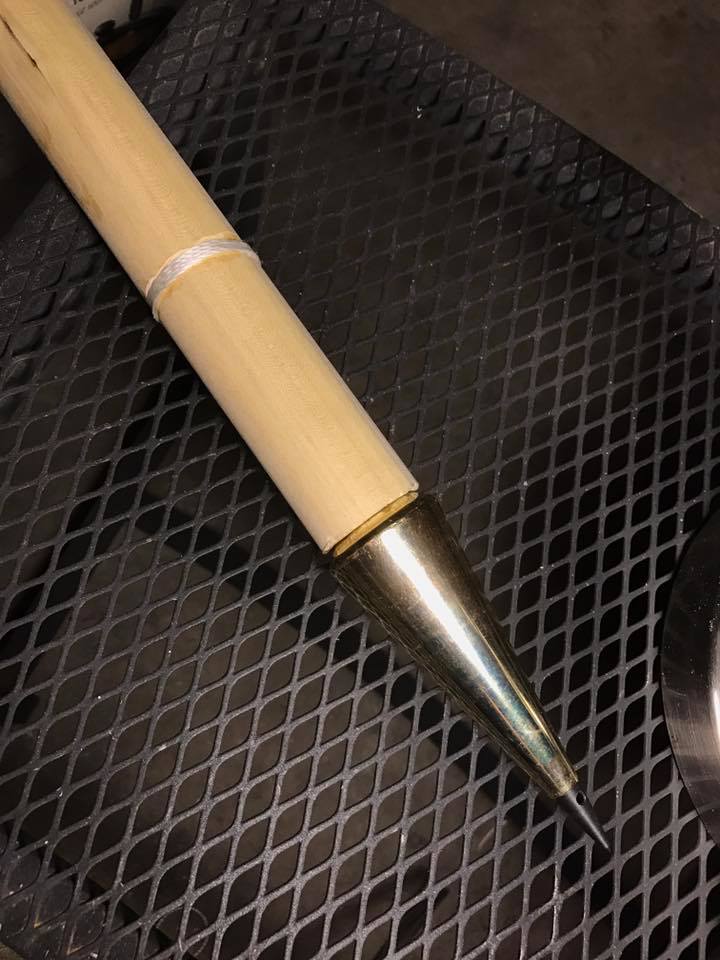

The handle and pummel are made the exact same way as my Altera Lance. A 1 pound plumb bob and a 1 3/8″ wood pole are used. A very deep hole is drilled in one end and then part made bigger to allow the neck of the plumb bob to be inserted.

A hole is drilled half way through the side of the pole, meeting with the larger hole up the pole. A groove is carved out to act as a trench for the twine. The plumb bob has twine attached to the neck, which is then screwed onto the body. The twine is the tightly wound around the trench and secured with a lot of super glue. This whole handle will later be wrapped. Then I cut the pole to a length of 18.”

Here, I wrapped the handle with a nice charcoal satin ribbon I acquired at Colorado Fabrics. It is wrapped very tightly, securing it with strips of duct tape several times along the way as shown. It must be wrapped and secured tightly or you risk the ribbon coming loose from use. The plumb bob was still able to spin so I secured it in place by packing the space with Worbla and taking full advantage of its highly adhesive properties. The black tip on the plumb bob was removed because its point is kind of sharp.

I drilled and carved a hole large enough to fit a 3/4″ wooden pole. The 3/4″ pole is inserted, adhered with Liquid Nails Extreme Heavy Duty (see important note below) and then secured in place with screws on one plane. I used a smaller pole for the spine of the sword and simply used the length of the handle I chopped off earlier (it was a long pole) because wood is heavy and I want the sword to be as light as possible. The less wood the better. Two larger screws are drilled into the handle close to the base of the hilt area, on the same plane as the two smaller ones, and alternating. Don’t worry, there’s method to my madness!

(Note from Hot Wire Foam Factory: Many glues will melt foam over time, or gradually expand, forming cracks in between layers. We have heard from numerous sign-makers who have reported that their lettering fell off their backdrops after 12-18 months, and they found a cavity where they had applied the glue. Also, you can cut through Hot Wire Foam Factory’s Foam Fusion and Styrogoo glues after they have dried. There are no other permanent foam-safe glues that allow this.)

I cut my pattern in half to ensure that the sword will truly be symmetrical. Trace it and then flip it over and trace it again. I got 3 slabs of 2’x8’x1″ blue XPS foam (ended up only needing 2). The pattern is pinned on and traced. The pattern is flipped and the resulting pattern is made. You’ll notice I left out the two cylinder things on either side of the hilt. Those will not be made with XPS foam so I did not include them here. The handle/spine assembly is traced on. This board will be the center layer of my 3-layer lamination.

Here’s where my madness makes sense. I am using Extreme Heavy Duty Liquid Nails on the entire length of the handle and spine but I need extra assurance that, if the adhesive were ever to fail, the poles cannot move freely within the body of the sword. Having screws on a single plane attached to the poles will prevent that from ever happening once the other two layers are glued on either side. The core the the blade is now complete.

XPS foam is extremely light so all the weight is in the handle. But even with the wood and the plumb bob, the center of gravity is still around the hilt and not the handle because the blade is so long while the handle is so short. If there’s no counter weight in the pummel, the center of gravity would be further up the blade, which means you’d be fighting just to hold it and you’re arms will get tired very quick. The other two layers are traced on a slab of XPS and cut out. A shallow groove was carved out to allow space for the big handle, which is thicker than one board. After the three pieces had a chance to cure for 24 hours, the pattern was traced on and spots for the PVC pipes to be inserted are drawn on the hilt. Ready for carving and sanding.

This was one of those times when you realize you need a tool you don’t have. There was so much carving required and this foam is so dense that a long blade simply wasn’t enough. Time to order a hot wire cutter from Hot Wire Foam Factory!

What a life saver! This is the Crafter’s Sculpting Tool with Wire Tensioner. After over an hour of carving with the Sculpting Tool, this is the result. All I needed to do was remove the big pieces and make a close shape of what I want.

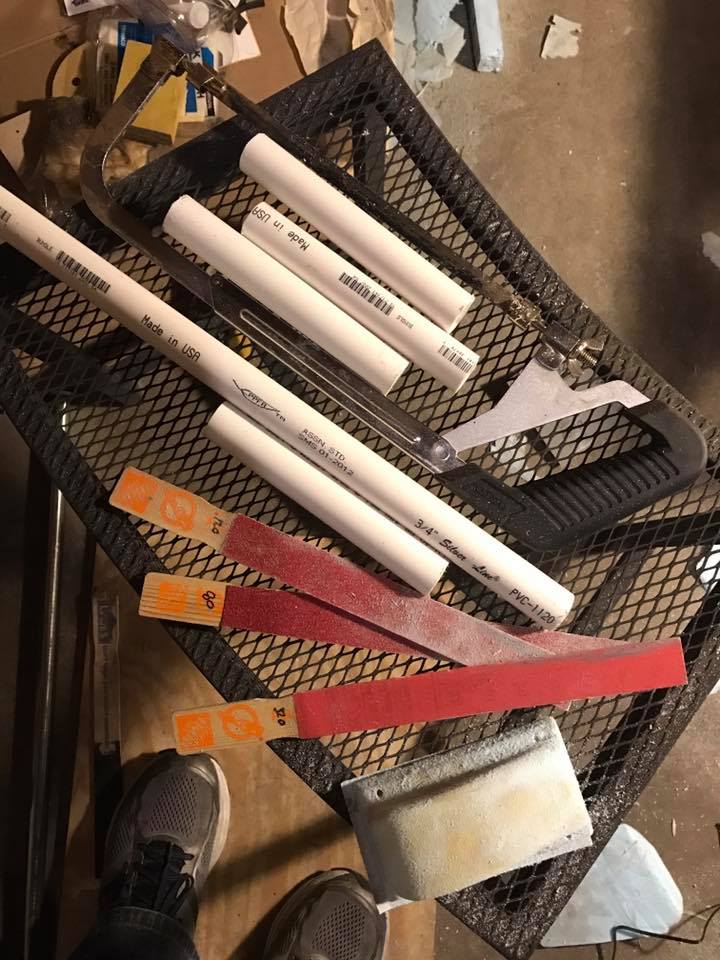

Sanded with a flat hand sanding block, first with 80 grit, then 120, then 320. I also used sanding sticks for small areas. Remember to wear face protection when sanding XPS foam; it goes everywhere and you don’t want it in your lungs or eyes. I then used an aluminum shower curtain pole to cut a few perfect circles into the foam for the hilt rods to go into.

The first photo above shows two things: First is the sanding sticks. I learned of these from Evil Ted. Take a paint mixing stick, spray on an adhesive like Super 77, stick on sand paper, and cut away. They are incredibly useful. The second is the PVC pipes. The hilt has two rods sticking out on either side. I cut out four pieces of pipe 6.75″ long. They will be secured to the hilt in those circles I cut. The Ultima Weapon is looking great! Although, the left side near the end needs a bit of rounding off.

Paper maché is lain on top of the XPS foam. The paper maché mixture I used was a one part water to one part Elmer’s Glue All. A newspaper was ripped into long strips about 1-2 inches wide, dipped in the mixture, excess mixture taken off, and placed on the sword in a closed lattice pattern. It needed to set and harden for several hours. Then I put on six coats of Spar Urethane, which was sanded smooth. Once fully cured after 24 hours, it’s relatively hard. It’s also relatively light weight, a very important benefit to large weapons like this. Because it is thin, you definitely need several coats. Make sure to sand after 2 hours of application; do not wait 24 hours to sand. Then, using my original pattern, I cut out the center design on 2mm EVA foam.

Though you can’t see it very well, I took an X-Acto knife and made a cut along the black lines, NOT going all the way through. When the foam is heat sealed, the cuts open up. The foam was then carefully glued on to the sword. There are Worbla support pieces at the bases of the hilt rods and caps made out of EVA foam for them. Once all the pieces of EVA foam are glued on and heat sealed, they’re ready for Plasti Dip.

The sword was covered with three coats of Plasti Dip. I used black for the hilt because it will be painted with dark colors and metallics, which are best painted on black. The spray paint I intended to use was a bit transparent, so I needed the blade to be totally white, covering all traces of newspaper. I painted on two coats of Folk Art Acrylic Titanium White to be sure it was covered. Then I used Tamiya Pearl White for the blade. For the edges, I airbrushed on Tamiya Clear Blue paint. In Final Fantasy VII, the Ultima Weapon changes color depending on Cloud’s health. When he’s low on health, it’s more purple. When his health is full, it’s a vibrant blue. The center EVA foam piece was painted black to prepare for its proper coloring.

Using Folk Art Acrylic Violet Pansy and a mix of either white or black, three shades of purple were prepared for the center design. I hand painted it in a gradient from the light purple to the dark. The technique for this is tricky and I can show how I do it if you need to see it. Using the same dark purple, the center arrow was painted. More painter’s tape was used to close off the center red diamond for painting. Three different shades of red, each having a tint of pink were prepared. The center diamond was painted the same way as the purple, only reversing the direction of the gradient. Tamiya Titanium Gold was used for much of the hilt. Instead of using a very fine paint brush for detail lines, I thought I’d try a paint marker. Worked quite well for some areas but a long but thin brush is still my go-to for fine lines. Using the larger amount of red I mixed up, the hilt poles were painted. These required 4 coats.

I wanted a satin finish to it so I used a satin enamel clear coat. Enamel also gives it a harder surface. One good coat was enough. Be careful not to apply too much in a single coat or it will drip on your prop. After that was dry, Ultima Weapon was finished!