EPS Foam Stucco Trim Fabrication Business

Why EPS in Construction?

- Economical, with high mark up and profit

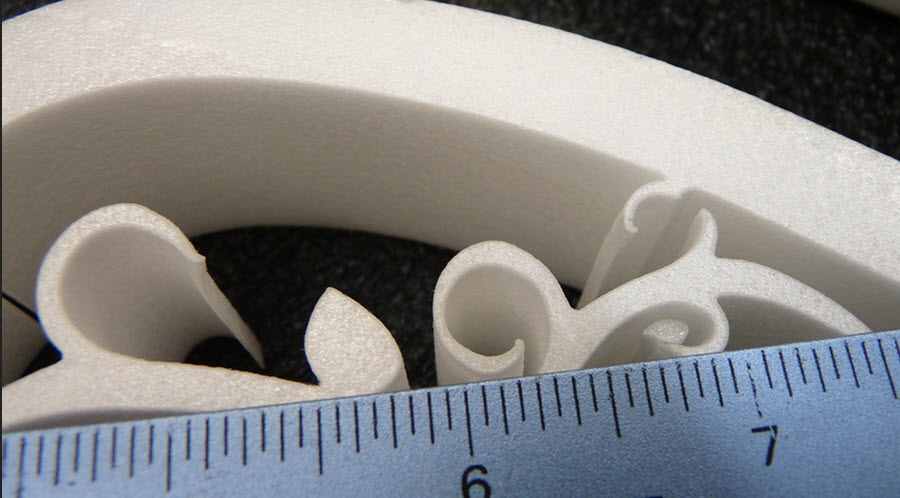

- Unlimited design potential

- Easily modified

- Excellent surface bonding to building materials

- High R-Value

- Environmentally friendly (Green building)

- Minimal installation tooling costs

- Lightweight, easy to handle, easy to coat

- Durable and strong, will not deteriorate or warp

- Class A fire rating

What Can EPS be used for?

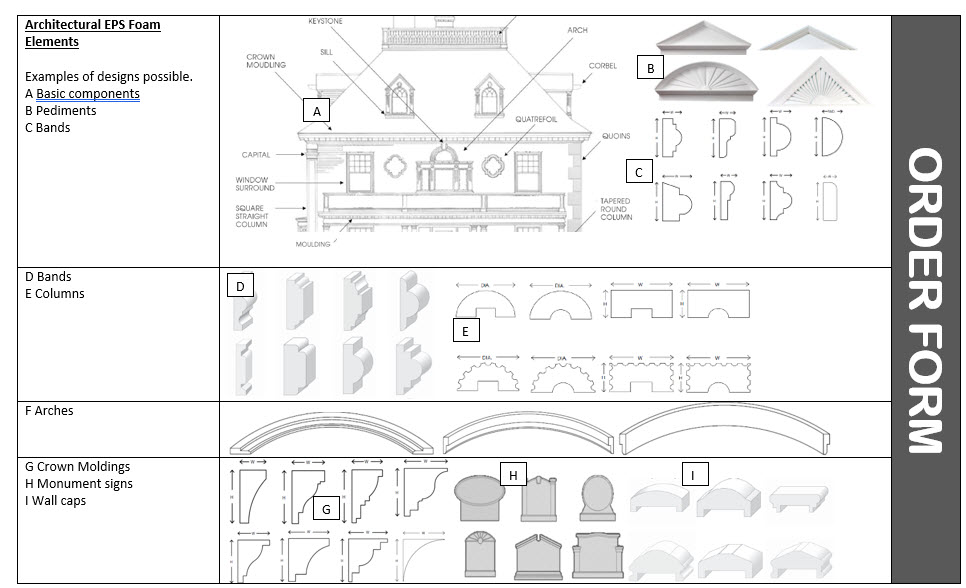

- Arches, balustrades

- Sills, bands, trim

- Columns, caps, corbels

- Crown moldings

- Pediments

- All sorts of custom 3D shapes

- Keystones

- Monument signs

- Quatrefoils, quoins, rosettes

“Just in time” fabrication means you stock EPS Foam blanks and custom cut for each job order or customer. Simple as:

- Inventory EPS foam blanks.

- Customer orders the style, sizes and quantity needed.

- Load the foam blanks onto the CNC and set the start point for cutting.

- You load up the shape profile on the computer, change the settings for sizes and any modifications needed, and start cutting. Keep the surrounding foam to protect the shape.

- Unload the foam, store until customer picks up the completed order or you install it at the construction site.

How Do I Build My Business?

- The HWFF XL CNC costs $12,400. Financing is available!

- We provide a free business/marketing plan you can adapt to your business.

- We provide you with support assistance in setting up your CNC.

- We will connect you with EPS Foam suppliers in your area.

- Online video training and phone-based and email support are provided as you start your fabrication business.

- We will give you a sample Order Form to use as a starting point for your own customer order forms.

- We provide a free WordPress template for your EPS Foam Fabrication business website; your own current webmaster can set it up, or we can recommend a contractor to set it up and maintain your site for you.

- An open Community Forum provides you access to other businesses, like yours, so you can provide mutual support.