Concrete Canoe Production Process

by: The Concordia University Concrete Canoe Team

We used the Original Scroll Table to cut cross sections of foam for our scaled mold. The scaled mold was used to determine the construction techniques that would be used for the full size canoe. Overall, we made 3 scaled molds, using different techniques.

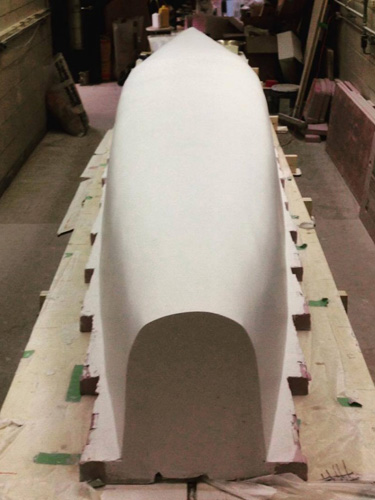

The 4-foot Bow Cutter was used to cut the full sized canoe. Cross sections are glued together to form the general shape of the canoe, which is then sanded down to the final shape. Concrete is then placed on the mold, along with reinforcing mesh.

Canoe mold ready for pouring.

The finished canoe can then be seen racing at the Canadian National Concrete Canoe Competition in Montreal.