Custom Ceramic Sink Mold

Dottie Natal

Here are the quick and simple steps to making a mold for a ceramic object.

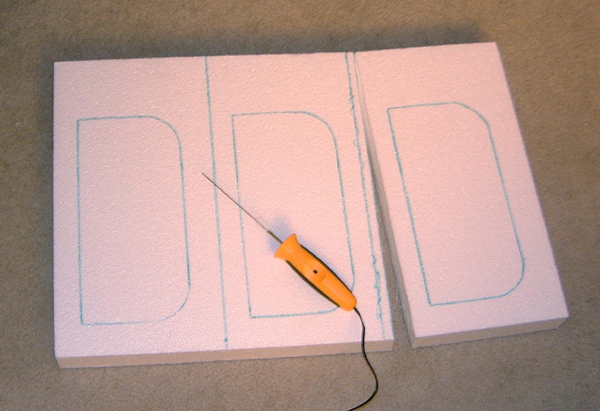

1. For a custom 6″ deep sink, Dottie cuts out three slices of low density EPS foam. First, the Hot Knife tool is used to cut the first slice. She makes a gentle angle towards the center, which will make it easier to remove the clay from the mold.

1. For a custom 6″ deep sink, Dottie cuts out three slices of low density EPS foam. First, the Hot Knife tool is used to cut the first slice. She makes a gentle angle towards the center, which will make it easier to remove the clay from the mold.  2. The top of the second slice is marked with an outline of the bottom of the first slice, so they will match up. The second slice is now cut, also with a gentle taper in. The last slice is left flat so the sink’s drain will seal.

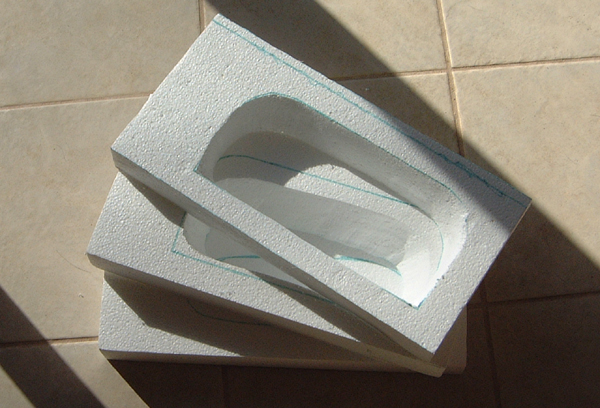

2. The top of the second slice is marked with an outline of the bottom of the first slice, so they will match up. The second slice is now cut, also with a gentle taper in. The last slice is left flat so the sink’s drain will seal. 3. The three foam slices are glued together with a few dots of low temperature hot melt glue. She doesn’t use too much glue, because she wants to be able to re-use the mold.

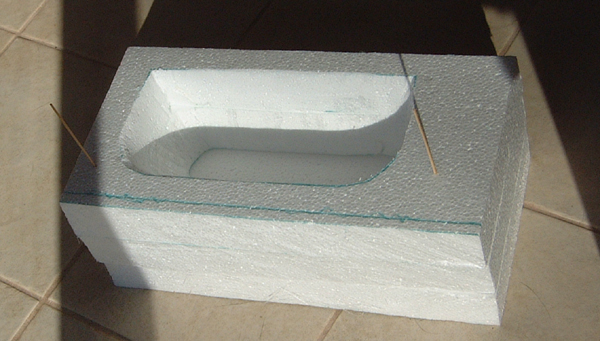

3. The three foam slices are glued together with a few dots of low temperature hot melt glue. She doesn’t use too much glue, because she wants to be able to re-use the mold.  4. Dottie applies the clay to the mold, cuts out the drain and faucet holes, and then lets the clay dry.

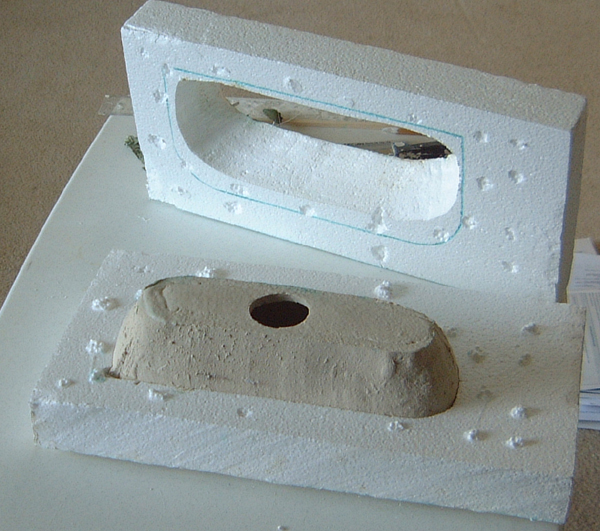

4. Dottie applies the clay to the mold, cuts out the drain and faucet holes, and then lets the clay dry.  5. The mold is taken apart.

5. The mold is taken apart. 6. Dottie cleans up the clay sink before firing.

6. Dottie cleans up the clay sink before firing.