Part 1: CNC Cutting

As with all foam projects, this build starts with acquiring the right materials. In this case, the team needed some massive foam blocks.

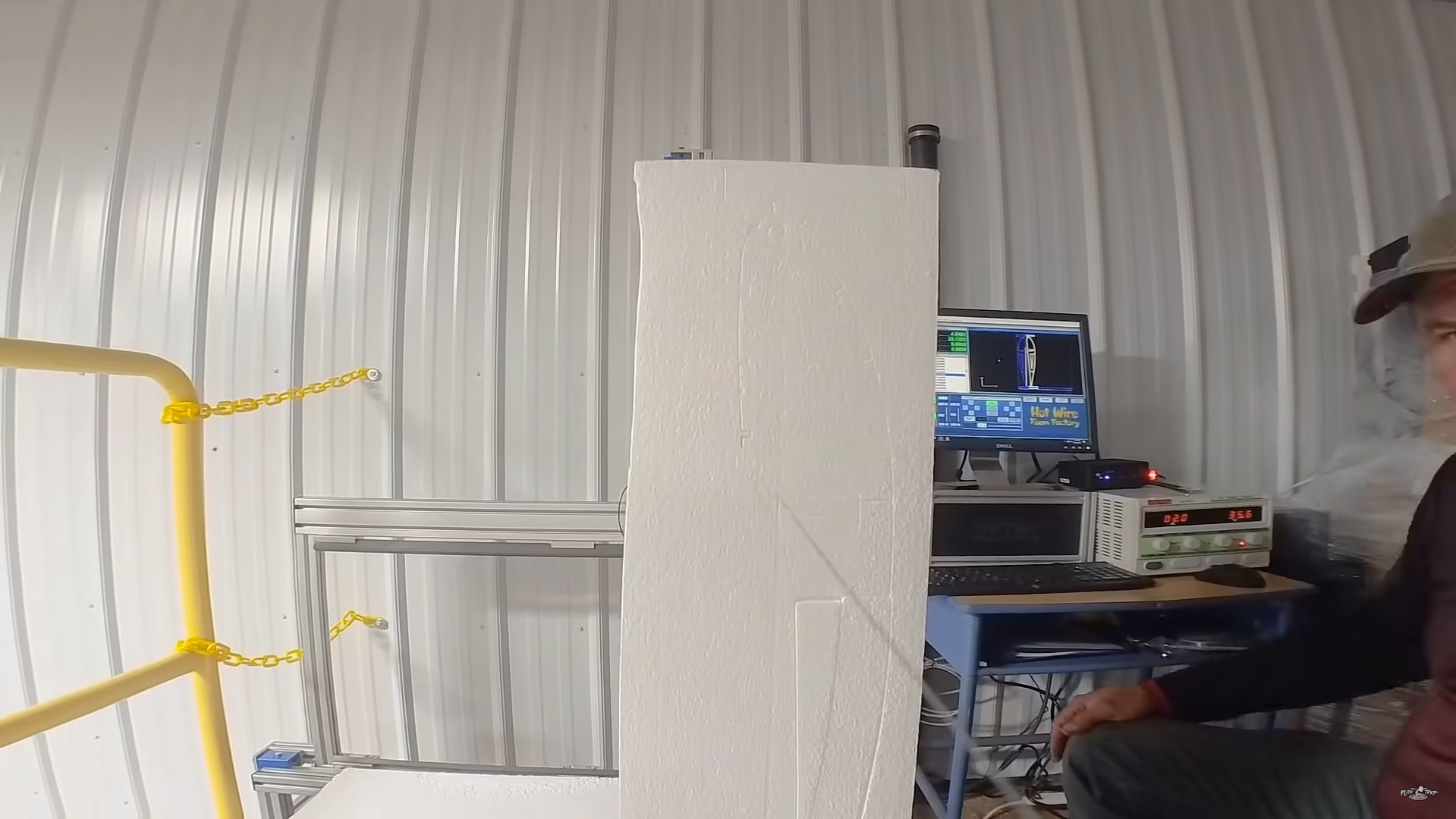

After getting the blocks lifted to their CNC area, they started cutting out the wings. The wings were cut into 3 sections, with the longest segments being made on the XL CNC and the smallest being made on the Aero.

Next, they cut out sections of the fuselage on the Aero CNC.

With the pieces cut out, they laid them out as they would fit together.

They assembled the pieces of the wings to make sure they fit together. The entire wing assembly weighed just under 7 pounds.

Next, they cut out the wind shield using wood templates created from a 3D model section and the 4-Foot Bow Cutter.

Video of Part 1: